我們博客的最新信息

利用ZAP-OX™的功能:革新製造效率和降低停機時間

在注射成型中,精度,效率和清潔度是關鍵。高標準的清潔度可確保產生高質量的組件並延長昂貴設備的壽命,最終使底線受益。汙漬或...的任何堆積

降低營業額和提高效率:納米納普拉斯如何幫助製造商簡化流程並賦予員工權力乐动体育官方网址

他們說,“魔鬼在細節上”,而且這比製造業務更為明顯。次要方麵可以顯著影響效率,並擴大底線。該原則對於所有行業,尤其是塑料注入都符合...

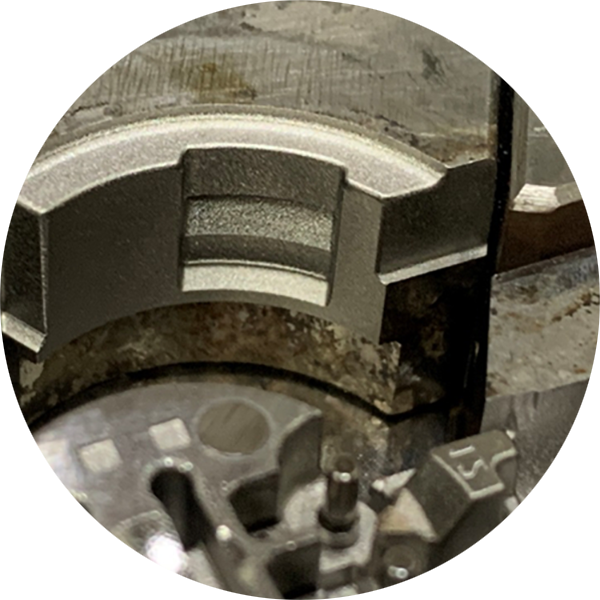

Min-Lube高性能油脂是工業機械必不可少的五個原因

工業機械需要高性能潤滑才能有效,有效,安全地運行。Min-Lube高性能油脂是注射成型的絕佳選擇,在嚴重的環境和食物中提供出色的保護和性能...